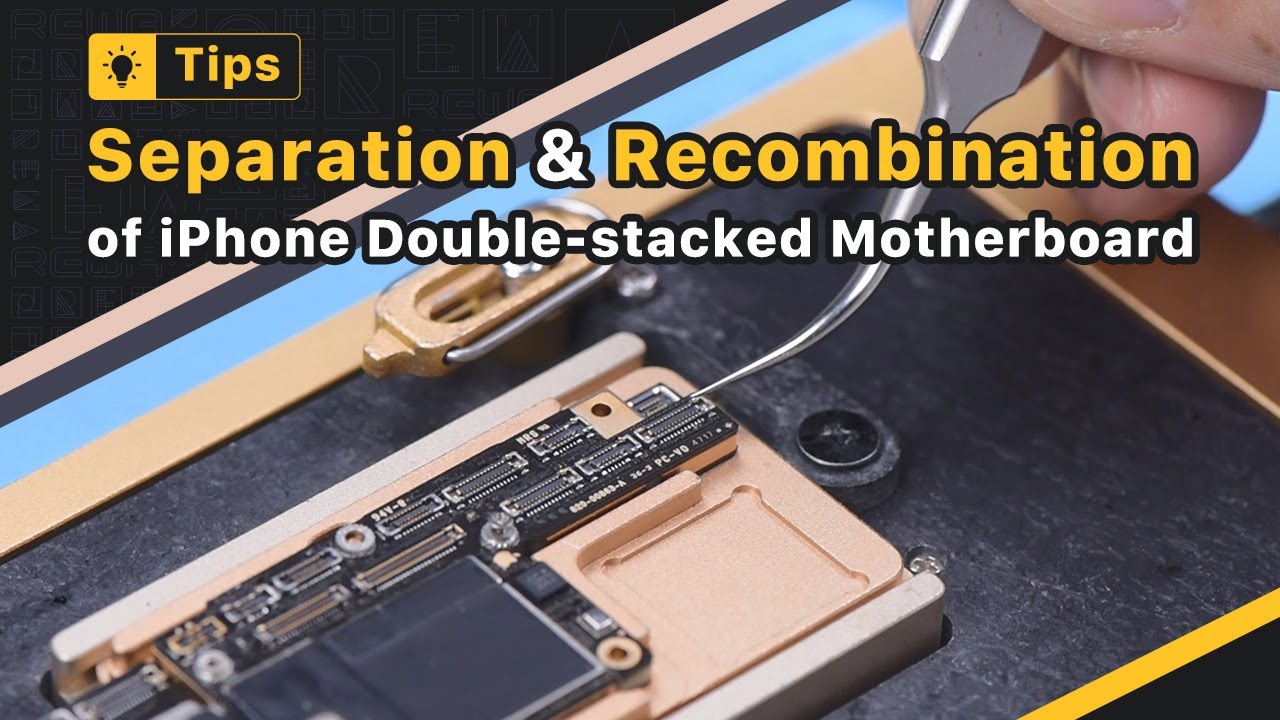

Lately, REWA Academy students offered responses that both layers often stop working to fit closely in double-stacked motherboard repair service There are also huge spaces, triggering quasi soldering In action, we will certainly share ideas and also notes when separating and also recombining double-stacked motherboard Remove foam on the motherboard before home heating Please be kept in mind that we do not suggest newbies to heat the motherboard with a warm air weapon Because the motherboard might receive warm erratically and also flaw A specialist motherboard home heating platform is what we recommend To promote later on elimination of the reasoning board, drive a screw on the logic board Cut through the tape with a Sculpture Blade The reasoning board and center layer are soldered with low-temperature solder paste So the most effective temperature level for the heating platform will be 155 ° C-165 ° C Press the reasoning board carefully with tweezers when the temperature level gets to 165 ° C If the reasoning board hangs, the tin has actually thawed Clamp the screw to get rid of the logic board Eliminate the signal board Remove thermal grease with a Sculpture Knife Thermal grease should be eliminated totally Or else, the thermal oil will certainly touch the logic board to trigger pseudo soldering in recombination Affix the signal board to the holder Apply a round of Paste Change Get rid of tin on the bonding pad with Soldering Iron at 365 ° C and also Solder Wick Tin on the bonding pad must be entirely gotten rid of The recurring tin will certainly affect the subsequent soldering Tidy the bonding pad with PCB Cleanser Clean the logic board with the exact same approach Please do not damage components around the bonding pad of the reasoning board while cleansing It is required to check if the bonding pad is neat after cleaning Attach the signal board to the Reballing System Put the reballing pattern ready to ensure that it is pressing versus the signal board To stop the solder paste from streaming right into the motherboard void, insert a steel plate Apply a layer of low-temperature Solder Paste Rub out excess solder paste with a Lint-free Wipe Remove the reballing pattern Check if solder paste on the signal board is complete While applying solder paste, please make certain that solder paste should have a certain moisture If the solder paste is also dry, it will certainly adhere to the reballing pattern when the stencil is removed Consequently, the solder paste on the signal board will not be consistent, which can easily bring about poor soldering Put the signal board on the 165 ° C Heating System to warmth Quit heating after the solder spheres are formed Apply a percentage of Paste Flux after the signal board has actually cooled Align the reasoning board with the signal board Keep heating on the 165 ° C Heating Platform When the solder flux spills as well as logic board sinks, nudge the logic board carefully with tweezers to make sure both layers fit very closely The push needs to be gentle as well as little Clean the motherboard with PCB Cleaner after the motherboard has actually cooled If you discover the motherboard deformed while recombining, you can put the motherboard on a level board and also fasten it with an elastic band Press two sides of the motherboard gently To avoid squashing parts, please put a soft paper under the motherboard Next, we will share another recombination approach The approach can be taken if the middle bonding pad is not harmed When the tin melts, get rid of the logic board in a vertical fashion with tweezers It can be seen that there is a metal pad of 0.05 mm thickness around the signal board at a particular distance This metal pad is made to maintain a 0.05 mm gap in between the reasoning board as well as the middle layer, preventing the solder balls from bridging while soldering You just need to get rid of thermal grease on the motherboard when the repair work is done Keep initial tin on the bonding pad Use a small amount of Paste Change Last but not least, line up the reasoning board with the signal board When the temperature level gets to 165 ° C and the tin melts, turn the power off Press two ends of the reasoning board with tweezers until the motherboard has actually cooled down The reasoning board and also the signal board fit closely in this way There will be no linking as well as solder spheres spillover Browse through REWA Academy if you intend to discover more repair service abilities We have complete training course packages for motherboard medical diagnosis as well as repair ability improvement Click the link in the comment section to purchase motherboard fixing program packages Thank you for viewing and do not hesitate to leave a remark